Semiconductor nanowires grown with precise control and placement, a step toward mass production

August 2, 2010

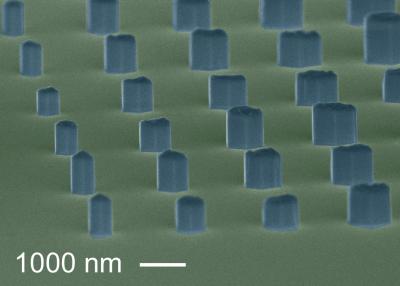

Semiconductor nanowires grown at NIST in a precisely controlled array of sizes and locations (K. Bertness, NIST)

NIST researchers have grown nanowires made of semiconductors–gallium nitride alloys–with precise control of diameter and placement by depositing atoms layer-by-layer on a silicon crystal under high vacuum. Precise control and placment are essential before nanowires can be widely used. Growing nanowires on silicon is one approach NIST researchers are exploring for making “nanowires on a chip” devices.

The latest experiments, described in Advanced Functional Materials*, maintained the purity and defect-free crystal structure of NIST nanowires while controlling diameter and placement better than has been reported by other groups for catalyst-based nanowires. NIST also has the unusual capability to produce these nanowires without using metal catalysts, thereby enhancing luminescence and reducing defects.

The key trick in the NIST technique is to grow the wires through precisely defined holes in a stencil-like mask covering the silicon wafer. The NIST nanowires were grown through openings in patterned silicon nitride masks. About 30,000 nanowires were grown per 76-millimeter-wide wafer. The technique controlled nanowire location almost perfectly.

Although the growth temperatures are too high—over 800 degrees Celsius—for silicon circuitry to tolerate, there may be ways to grow the nanowires first and then protect them during circuitry fabrication, lead author Kris Bertness says. The research was partially supported by the Defense Advanced Research Projects Agency (DARPA) Center on NanoscaleScience and Technology for Integrated Micro/Nano-Electromechanical Transducers (iMINT) at the University of Colorado at Boulder.

* K. A. Bertness, A. W. Sanders, D. M. Rourke, T. E. Harvey, A. Roshko, J.B. Schlager and N. A. Sanford. Controlled nucleation of GaN nanowires grown with molecular beam epitaxy. Advanced Functional Materials. Published online: July 13, 2010. DOI: 10.1002/adfm.201000381

More info: National Institute of Standards and Technology (NIST) news