Berkeley Lab researchers achieve nanoscale shape-memory effect

December 5, 2013

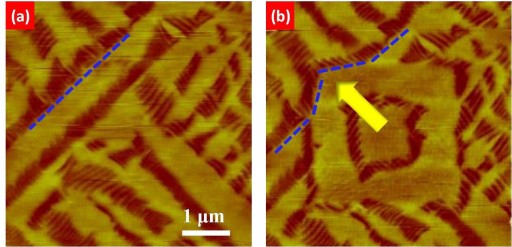

This AFM image shows a recoverable phase transformation in a bismuth ferrite film introduced by an applied electric field. The dashed blue line shows the relocation of the phase boundaries. (Credit: Ramesh et al./Lawrence Berkeley National Laboratory)

A research team at Berkeley Lab has discovered a way to introduce a recoverable strain into bismuth ferrite of up to 14 percent on the nanoscale, larger than any shape-memory effect observed in a metal. This discovery opens the door to applications in a wide range of fields, including medical, energy and electronics.

“Our bismuth ferrite not only displayed the champion shape-memory value, it was also far more stable when reduced to nanometer size than shape-memory alloys,” says Jinxing Zhang, a post-doc for this study under Ramamoorthy Ramesh of Berkeley Lab’s Materials Sciences Division and now a faculty member at Beijing Normal University.

“Also because our bismuth ferrite can be activated with only an electrical field rather the thermal fields needed to activate shape-memory alloys, the response time is much faster.”

How to extend the shape-memory effect to the nanoscale

The shape-memory effect is the metallic equivalent of elasticity, in which a solid material “remembers” and recovers its original shape after being deformed by an applied stress. In the past, this has always involved heating. Shape-memory alloys have had a big impact in the medical field with the most prominent being nickel-titanium or “nitinol,” which is used in stents for angioplasty, and in mechanical joints.

The shape-memory effect is also expected to have a major impact in non-medical applications, such as actuators in smart materials and in Microelectro-Mechanical Systems (MEMS). However, as the size of current shape-memory alloys shrink towards the nanoscale, numerous problems and instabilities arise, including fatigue, micro-cracking and oxidation.

“By achieving the shape-memory effect in an oxide material rather than a metal alloy, we eliminate the surface issues and enable integration with microelectronics,” says Zhang. “Our bismuth ferrite also displays an ultra-high work-function density during actuation that is almost two orders of magnitude higher than what a metal alloy can generate.”

“The application of the electric field allowed us to achieve a phase transformation that was reversible without the assistance of external recovery stress,” Ramesh says. “Yhe large shape-memory-effect we demonstrated in bismuth ferrite shows it to be an extraordinary material with potential use in future nanoelectromechanical devices and other state-of-art nanosystems.”

Abstract of Nature Communications paper

Stimulus-responsive shape-memory materials have attracted tremendous research interests recently, with much effort focused on improving their mechanical actuation. Driven by the needs of nanoelectromechanical devices, materials with large mechanical strain, particularly at nanoscale level, are therefore desired. Here we report on the discovery of a large shape-memory effect in bismuth ferrite at the nanoscale. A maximum strain of up to ~14% and a large volumetric work density of ~600±90 J cm−3 can be achieved in association with a martensitic-like phase transformation. With a single step, control of the phase transformation by thermal activation or electric field has been reversibly achieved without the assistance of external recovery stress. Although aspects such as hysteresis, microcracking and so on have to be taken into consideration for real devices, the large shape-memory effect in this oxide surpasses most alloys and, therefore, demonstrates itself as an extraordinary material for potential use in state-of-art nanosystems.