Making polymer composite materials to order

May 27, 2011

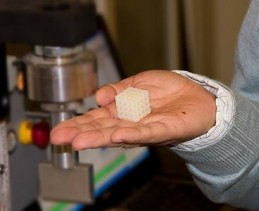

MIT researchers have found a way to make complex composite materials whose attributes can be fine-tuned to give various desirable combinations of properties such as stiffness, strength, resistance to impacts, and energy dissipation.

The team combined two polymer materials with quite different properties: one that is glass-like, strong but brittle, and another that is rubber-like, not so strong, but tough and resilient. The result was a material that is stiff, strong, and tough, the researchers said.

The key feature of the new composites is a “co-continuous” structure of two different materials with very different properties, creating a material combining aspects of both. The co-continuous structure means that the two interleaved materials each form a kind of three-dimensional lattice whose pieces are fully connected to each other from side to side, front to back, and top to bottom.

The researchers said that the process can be used to make materials with “tunable” properties: for example, to allow certain frequencies of phonons (waves of heat or sound) to pass through while blocking others, with the selection of frequencies tuned through changes in mechanical pressure. It can also be used to make materials with shape-memory properties, which could be compressed and then spring back to a specific form.

Mary C. Boyce, et al., Co-Continuous Composite Materials for Stiffness, Strength, and Energy Dissipation, Advanced Materials, 2011; 23 (13): 1524 DOI: 10.1002/adma.201003956